Using energy as efficiently as possible is one of the great social tasks of our time. Because of this, advanced energy management is now deeply anchored in the Dorfner organization. Right now, a project is starting which is intended to leverage further energy-saving potential.

Extraction of raw materials, processing, refinement, transport: The value creation processes at Dorfner require a considerable amount of energy. Because energy is a precious commodity, strategic energy management is a decisive factor for corporate success. It is also an important key to conserving resources and protecting the environment. Topics that have been the focus of the family business for decades.

Numerous measures have already been implemented at Dorfner which have made more efficient use of energy and sustainable generation possible. Between six and eight percent of the investment volume goes into projects that help reduce energy consumption. Around 40 percent of electricity is already produced in our own combined heat and power plants (CHP plants) and raw materials are being used more efficiently thanks to a new, sustainable recycling strategy.

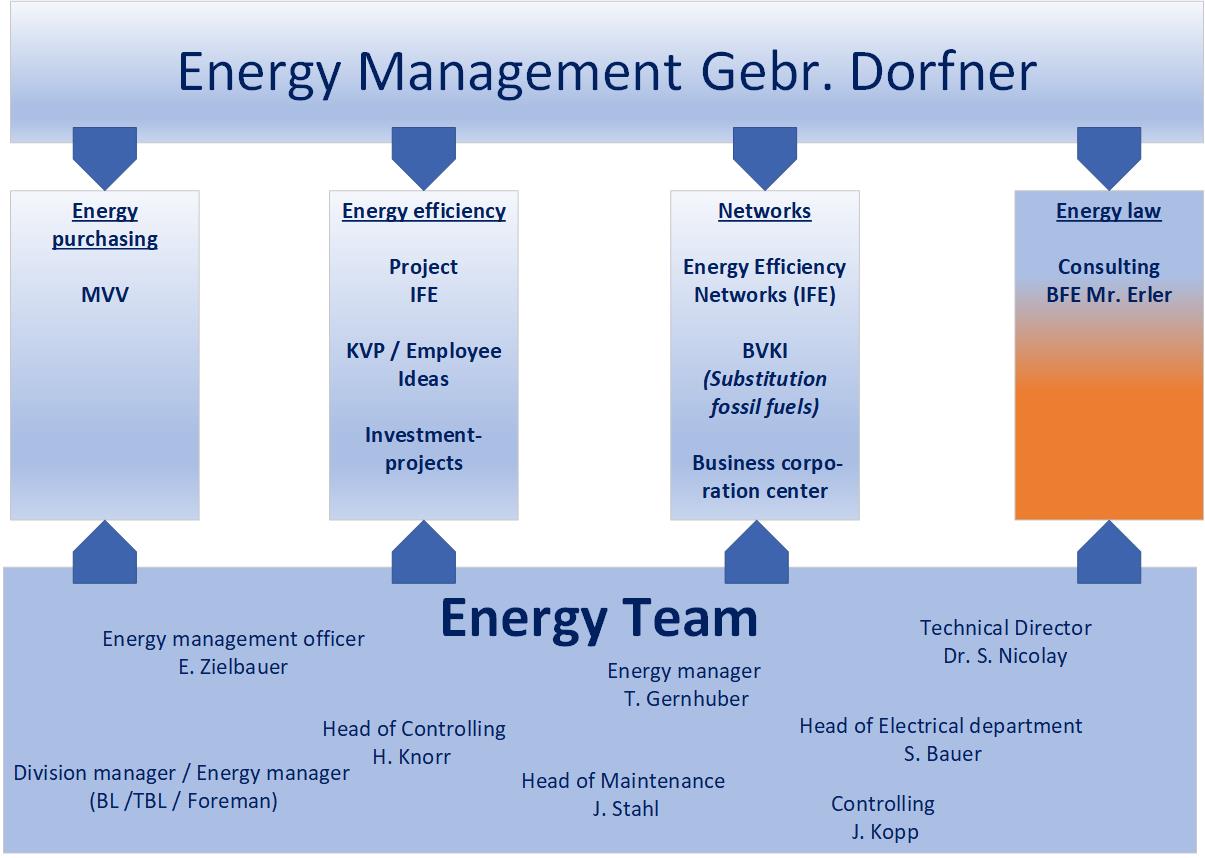

What is new is that energy management – i.e. the planning and control of energy generation, purchasing and use – is in the hands of an energy team at Dorfner. Thomas Gernhuber, technical buyer and energy manager of the company since 1 August 2020, sets about identifying and exploiting additional efficiency potential with seven other colleagues in his team. To this end, the energy team exchanges information across the organization, for example within the Energy Efficiency Networks initiative, and also accesses external support.

A project is currently starting with the Institute for Energy Technology (IFE) at the East Bavarian Technical University of Amberg-Weiden, which will examine all areas of the company in order to uncover possibilities for increasing energy efficiency. In addition to the production plants as major consumers, topics such as waste heat utilization, CHP optimization, vehicle fleet electrification and process optimization are also analyzed and evaluated.

The project duration is set at around 18 months. The results will help Dorfner go further along the path it has embarked on to continue its energy efficiency success story.

Thomas Gernhuber / Erich Zielbauer