Dorfner has signed a declaration of intent with BioPowder, a supplier of sustainable natural granulated materials, for a long-term supplier and customer relationship. This collaboration aims to refine, blend and manufacture cutting-edge functional fillers based on renewable raw materials and Dorfner technology.

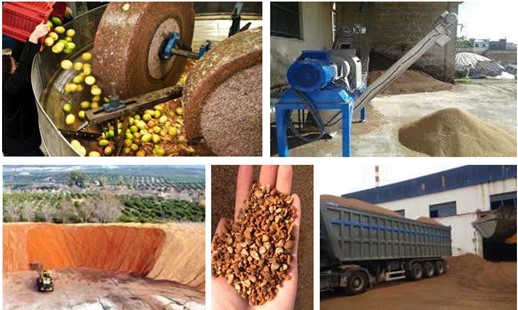

BioPowder, launched in 2017, is an expert in the granulation and micronization of natural, renewable raw materials such as olive pits. This method is based on decades of experience in the olive biomass-processing industry. BioPowder’s production facility in Andalusia, the heart of Spanish olive cultivation, consists of state-of-the-art grinding and sieving machines.

Sustainable raw materials

Long-standing relationships with local farmers and fruit processing companies afford BioPowder direct access to top-quality raw materials. The company’s efforts to promote sustainability focus on fair trade, local or regional sourcing, and processing agricultural byproducts instead of crops, eliminating competition with the food chain. The virtually emission-free production refrains from using chemicals, additives, or large volumes of drinking water.

High-tech for natural materials

The natural granules and functional powders from BioPowder are produced with extreme precision in a wide range of made-to-measure grain sizes. These granules are used as bio-additives or natural functional fillers in various solvent-based and non-solvent-based formulations, such as paints and coatings. Thanks to the collaboration with BioPowder, in addition to the industrial minerals that are mined to a large extent by Dorfner, the company is now able to refine these renewable natural granules.

Wide range of applications

The lightweight and highly stable natural granules from BioPowder, which are refined using Dorfner’s expertise, are used, for instance, as sustainable coated color granules and ultra-fine fillers in coatings, composites, and flooring systems.. As always, innovative solutions can be developed and tested to meet individual customer needs with the help of Dorfner’s application engineering services.

Further steps possible

The combined know-how of Dorfner and the Spanish expert for bio-additives opens up a wide range of new market opportunities. The agreement currently allows for the marketing of refined and non-refined core products under the Dorfner name and the refining or blending of core products for applications and markets under the BioPowder brand. Depending on success, the commercial and technical collaboration may be extended through long-term contracts.

Mathias Kuhnt