ANZAPLAN is preparing for the continuously increasing demand for raw materials for the mobility concepts of the future. A state-of-the-art hydrometallurgical pilot plant was set up to complement our existing pilot plant.

We can see every day how fast e-mobility is advancing. Car makers and battery manufacturers all over the world outplay each other to announce the building of new factories and the expansion of production goals. The technological change currently taking place means that there is a rapidly growing demand for battery raw materials such as graphite and lithium, which are used as anode and cathode materials in lithium ion batteries.

The huge material requirements which are now predicted can only be compared with the hunger for raw materials at the beginning of the industrial revolution. Pursuing the development path taken, which focuses on the sustainability aspect (decarbonization), we must expect historically unprecedented raw material requirements in the coming years for example for lithium and graphite, but also for rare earths, high-purity silica or special nickel compounds. They are indispensable in the relevant hydrogen technologies, such as lithium ion high-performance storage, solid-state batteries, electric traction motors, wind turbines, computer chips and high-performance permanent magnets.

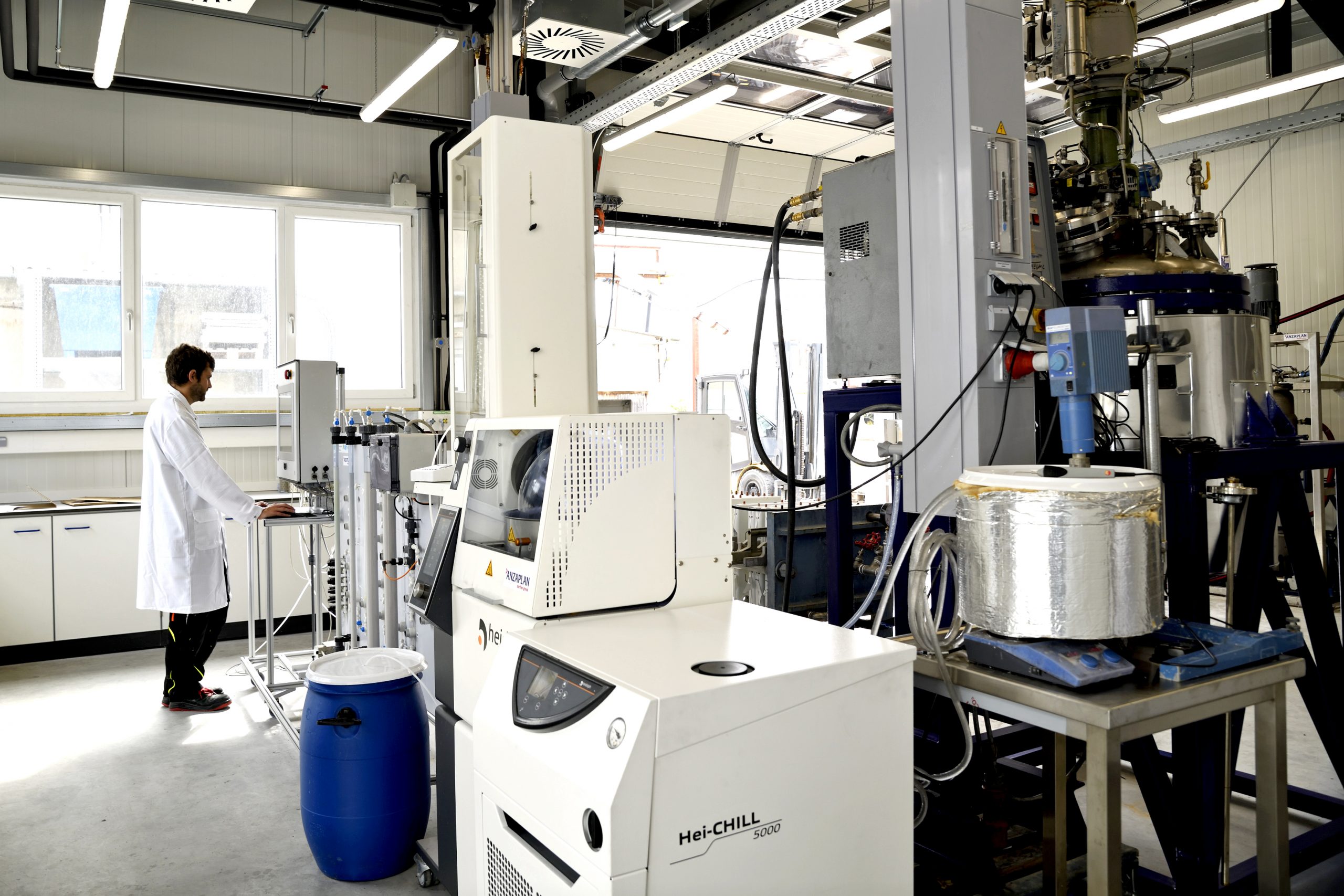

Against this background, ANZAPLAN built a state-of-the-art hydrometallurgical pilot plant right next to the existing pilot plant. It is intended for consistent further expansion of our product portfolio for pilot projects, process validation, and sample production of the high-value added raw materials which are in particularly high demand.

The pilot plant offers the best conditions for flexibly transferring the processes developed in the laboratory and tailored to the specific raw material and customer requirements to pilot scale. Process units such as calcination, leaching, precipitation, ion exchange, evaporation and crystallization are combined in such a way that the desired quantities and qualities of the products can be provided individually according to customer requirements. Besides the creation of samples, the generation of process data required for reliable engineering and upscaling of the plant to production size is an important part of pilot project planning.

Another innovative improvement is the equipment of the pilot plant with control cabinet and programmable logic controller (PLC). Thus, we can customize the automation of the pilot operation and also provide for continuous operation over a period of weeks.

The newly created hydrometallurgical pilot plant is thus a further milestone in adapting ANZAPLAN’s product portfolio to the worldwide demand for raw materials for rapidly growing advanced technologies, and for providing our customers promptly and competently with comprehensive services.

Dr. Sebastian Prinz